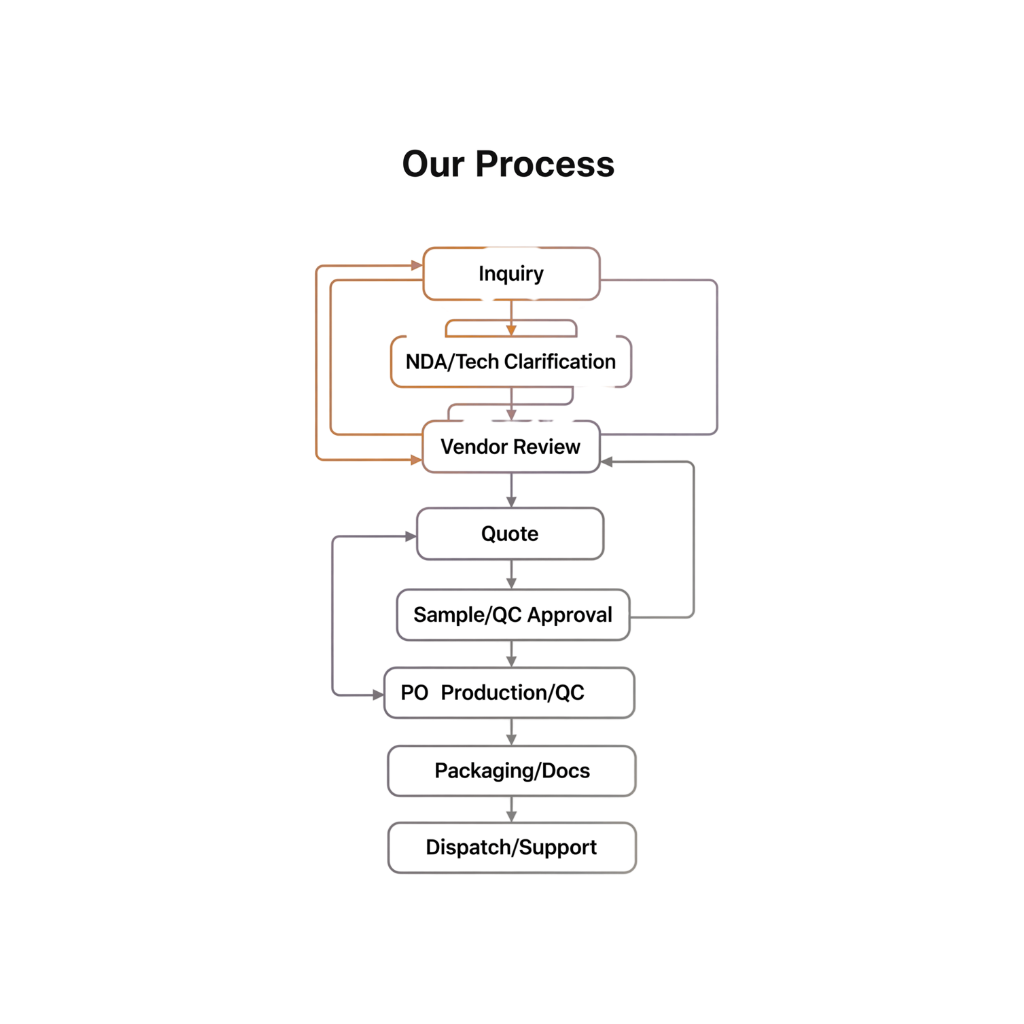

Our Proven Sourcing Workflow

We follow a structured, engineering-led process to ensure quality and efficiency at every step

Requirement Capture & Feasibility Check

We start by understanding your needs, executing NDAs if required, meticulously reviewing engineering drawings and BOMs, clarifying specifications (material grade, quality, compliance needs), and conducting a risk analysis for manufacturability and sourcing feasibility.

Supplier Engagement & Techno-Commercial Proposal

We select qualified vendors from our vetted network, share technical specifications for costing and lead time assessment, facilitate DFx reviews if needed, and submit a detailed proposal with cost, timeline, and scope.

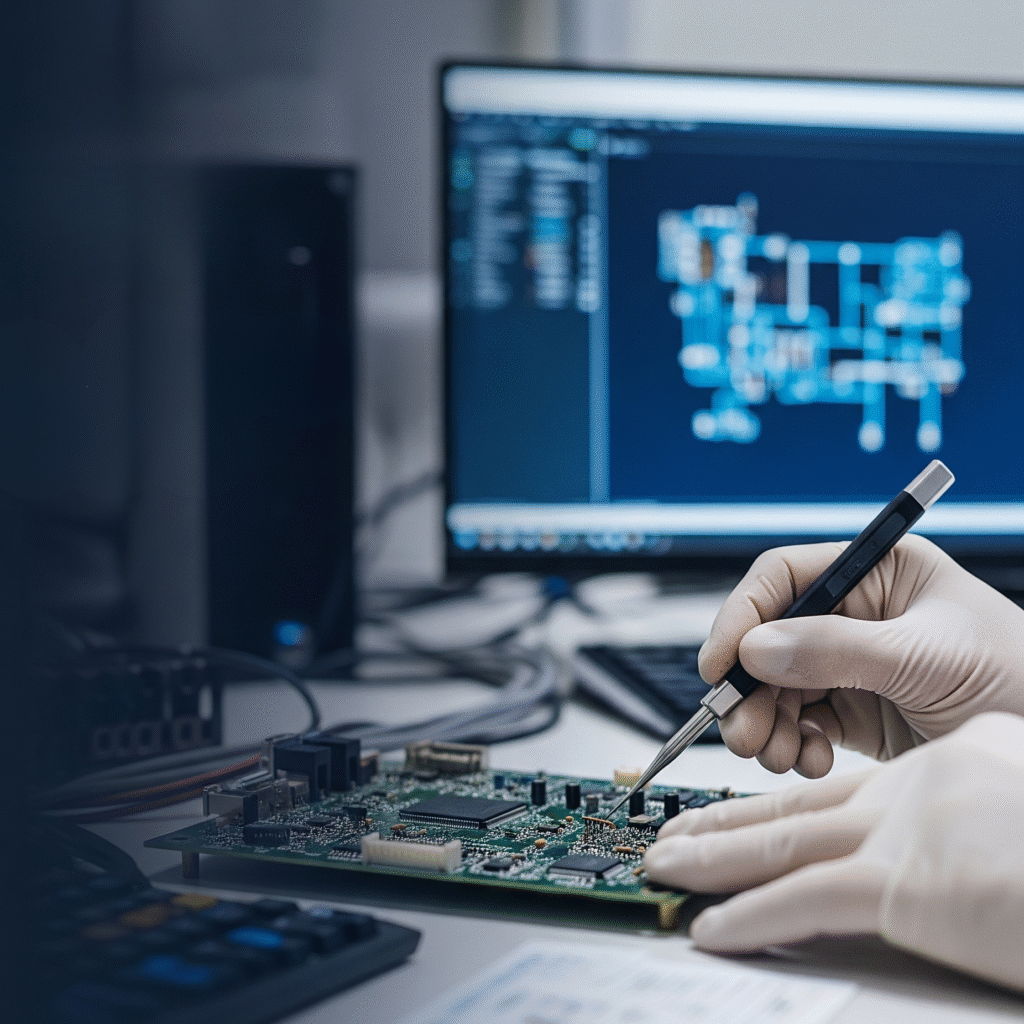

Sampling & Proto-Run Execution

We oversee sample manufacturing with detailed inspection reports, perform on-site quality checks before dispatch, and provide dimension reports, surface finish photos, and material certificates as per RFQ.

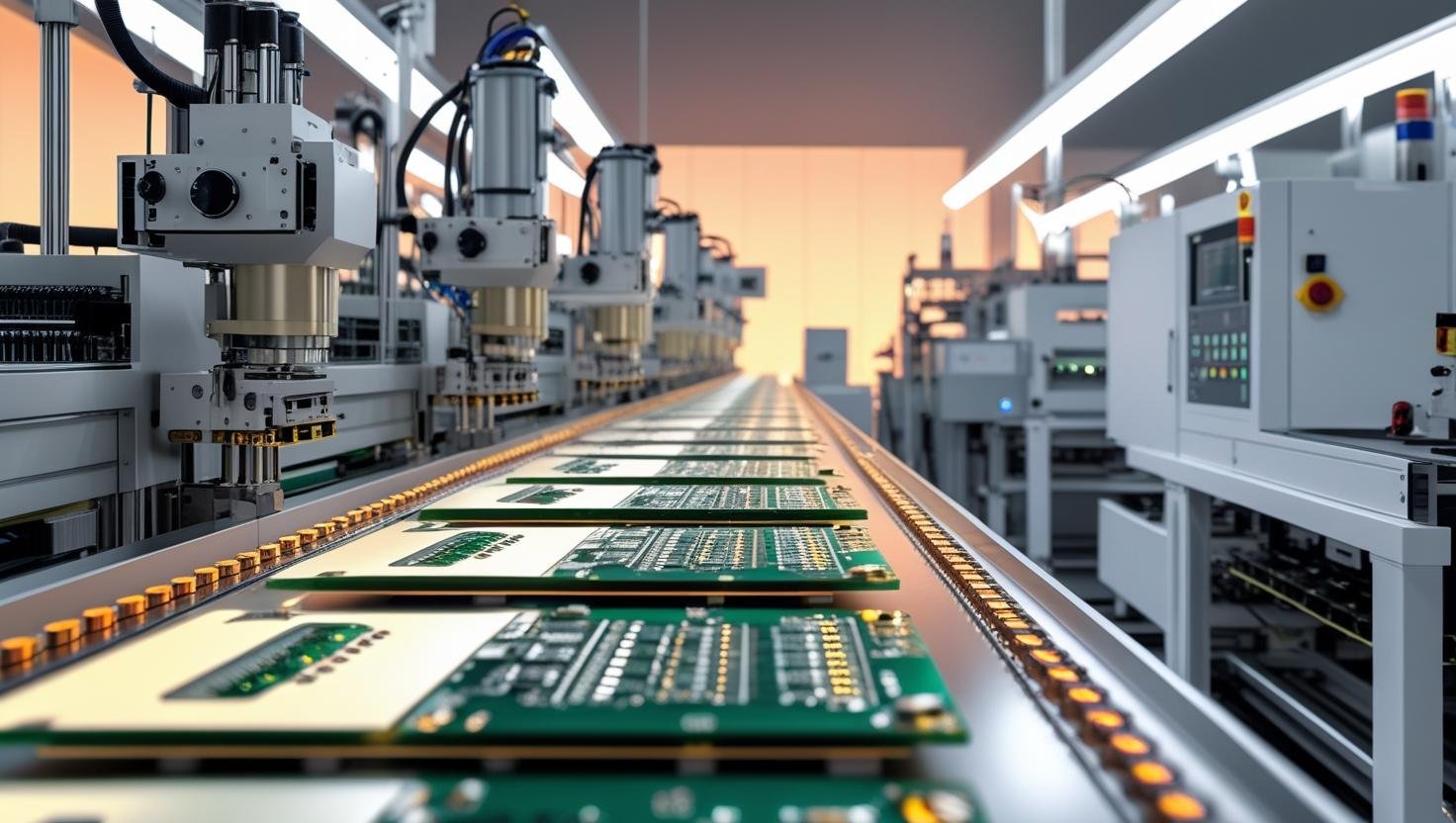

Volume Production & Monitoring

Upon approval, we place the volume order, track production milestones, provide weekly updates, and implement continuous quality assurance during production.

Export-Ready Packing & Logistics

We ensure robust packaging for air/sea transport, manage all export documents (commercial invoice, packing list, CoO, MSDS if applicable), and coordinate logistics with preferred forwarders or offer DAP/DDP support.

Post-Delivery Technical Support

Our commitment includes warranty support (if agreed), engineering change order implementation, and evaluation for repeat orders or scalability planning.